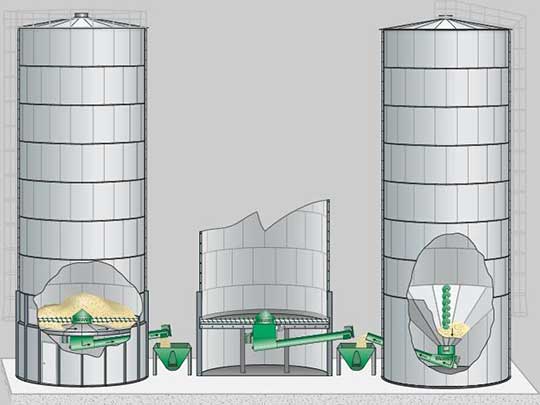

Cement silo

Cement silo, also called cement bin, cemnet container or cement storage silo, is widely used for storing cement in cement production plants. Flyer steel silos are all spiral silos with abundant technical strength and prominent performance. With unique, manufacturing method, professional equipment, mechanized operation, Flyer cement storage silo is famous for its solid structure and durability.Cement silos are on-site storage containers used for the storage and distribution of various types of cement mixtures. Spiral steel silos for storing cement cannot be removed and they are widely used in industrial production. Silos of this type come in a variety of sizes, making them ideally used in many cement plants. Flyer is a professional manufacturer that produces high quality spiral cement silos and provides service from design, manufacture to install fitting according to the clients' requirements.

Flyer Cement Silo's Features

- Long service life: The thickness of spiral seaming edge is five times of the original steel plate, which greatly strengthens the resistance of the loading and prolongs the service life of silos. In addition, the durable cement silos also guarantee a low maintenance cost.

- Short construction period: Our seaming machine can provide a 3-5m per minutes' shaping speed. A cement silo with a capacity of 1000 tons could be constructed within 5-7 days.

- Low investment: Compared with concrete silo, spiral cement silo only needs several people and seaming machine.

- Moisture resistance: Our silos are constructed by special bending equipment, and the steel bending is tight with good sealing property. Cement inside the silos can't be influenced by the outside environment like wind and rain, etc.

- Galvanized cement steel silo: The surface of galvanized steel silo is smooth and the cement can’t adhere to inside wall of silo in block.

Cement storage silo's working principle

- Before constructing the cement silo, the bottle base of the silo must be erected by a dedicated crane and be placed on the prefabricated concrete foundation. Check out the perpendicularity of the erected silo and weld the base bottom of the silo with the embedded foundation firmly.

- After the cement silo is constructed, cement can be transported into the cement silo by the pneumatic pressure of bulk cement truck if the transport pipe of cement truck connects with the feeding tube of cement silo.

- During the transporting process, the operator must press on the button of dust vibration motor to shake off the cement attached on the bag of dust catcher. Otherwise the cement may block inside the bag, silo explosion may occur.

- If cement block the bag, the pressure inside the silo exceeds the security pressure of the relief valve, the relief valve will open up immediately to release pressure inside the silo.

- Cement storage system is usually installed with material level measuring system, it shows where the position of cement.

How to build a steel silo?

- Prepare the necessary equipment for building steel silo based on the diameter of the silo.

- Build the steel storage silo to the height of 2 meters or more, and then build the silo's roof.

- Install steel silo's roof: using cutting machine to make the silo roof horizontal and then install the silo roof

- Build the steel silo up to the designed height, and then pull out the machine, drop the silo on the ground, make the silo body connects with pre-embedded parts in the ground.

Why choose Flyer cement silo?

- 1. Selecting superior materials: High intense hot rolled double galvanized coil are used to ensure steel silo's combination of stability, anticorrosion, air proof and good looking.

- 2. Short construction period: Short duration can be guaranteed for the onsite construction during the whole procedure and for our professional equipment can provide a 3-5m per minutes' shaping speed, so a cement silo with a capacity of 1000 tons could be done within 5-7 days.

- 3. Saving resources: Cost-effectiveness can be achieved for light sheets are used for the whole silo which made it just as heavy as the rebar of concrete silo. Comparably small coverage that could narrow the separation distance down to 500mm for maximized space utilization.

- 4. Wide range of cement silos' sizes: Flexible choices on dimensions are provided in a range of diameters from 3m to 28m, and a height of 35m in theory to meet various demands.

- 5. Advanced technology and equipments: High automation, advanced loading and unloading equipments provide you great convenience on operation and management. With abundant technical strength and prominent performance, Flyer Steel Silos are extensively applied in NSP cement production line as well as its corollary grinding station, and obtain a large market share.

- 6. Good reputation: High reputation among customers has achieved as more than 4000 steel silos have founded in China cement industry, and several NSP cement production lines have been set up for some large cement group like Tianshan Group, Qilianshan Group, Tongda Group, Washi Group and etc.

With advanced technology, unique manufacturing methods, professional equipment and mechanized operations, Flyer has successfully built many high quality steel silos. And Flyer will try its best to establish superior-quality steel silos to meet your own requirements, too! Feel free to contact us.